Sheet Metal Fabrication Sunshine Coast

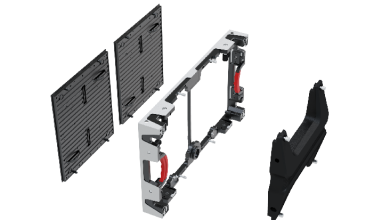

The process of sheet metal fabrication can be used by many industries to make products or components out of thin sheets. Most commonly, sheet metal fabrication involves punching and bending. This can be used to make products like brackets, covers and enclosures. Sheet metal fabrication Sunshine Coast by Turn Weld has many benefits, including increased efficiency and better durability.

You should be interested in metal fabrication if you want to make a profit for your company.

Sheet Metal Fabrication: Benefits for your Business

Metal Fabrication can save you time and money

Metal fabricators are able to save time and produce parts in a timely manner to meet deadlines. It will also save you money as there is no need to hire extra employees or buy expensive equipment like CNC machines.

Metal Fabrication can expand your product line

Metal fabrication allows companies to create new products that aren’t possible with other manufacturing processes, such as injection molding or stamping.

Metal Fabrication is Flexible

Metal fabrication is a different type of production than other types, which requires significant investment in machinery and equipment. Businesses can scale up without having to make significant changes to existing facilities or train workers on new equipment.

Metal fabrication allows you to make smaller quantities of products

Small batches of custom-made parts can be a better option than mass production in certain cases.

Raise Efficiency

You can increase your productivity by hiring certified metal fabricators that are familiar with the area they work in. They can produce small and large parts. They can reduce production times by up to 30% thanks to their expertise.

Quality Assurance

Quality assurance is the process of ensuring that products are manufactured to a high standard. Metal fabrication employs many exact machines to ensure quality. Your product will be free from defects as long as the manufacturers adhere to strict standards and conform with state legislation.

Reduce waste

Metal fabrication is eco-friendly. Metal manufacturing is more environmentally friendly than traditional methods that use raw materials such as wood, paper, and glass. This type of waste can be properly disposed off and helps to preserve natural resources.

The World Bank estimates that aluminum recycling rates are 70% and plastics recycling is 50%. Steel is only 30%. These numbers show how dependent we are on metal, which is threatening our planet’s future.

The bottom line

Metal fabrication involves cutting, bending and assembling metals to make products. This versatile technique can be used in many industries. Employing metal fabricators as staff can help you reduce costs. You don’t have to hire more people or buy expensive equipment. Metals can be used as raw materials to create new products or improve existing ones. This saves you money over the long-term because they won’t need to be replaced as often.